Until a dozen years ago CNC machining used to be the preserve of large industrial plants. Today, small and medium-sized enterprises also have access to this technology, which allows them to produce faster, more precisely and more cheaply.

At a time when competition is increasing and customers expect short lead times and high quality, investing in CNC becomes not only possible - but above all profitable.

Companies such as Eurotech CNC offer flexible cooperation models and production tailored to the needs of SMEs, allowing them to benefit from the advantages of modern machining without having to build up their own technology base.

What exactly is CNC machining?

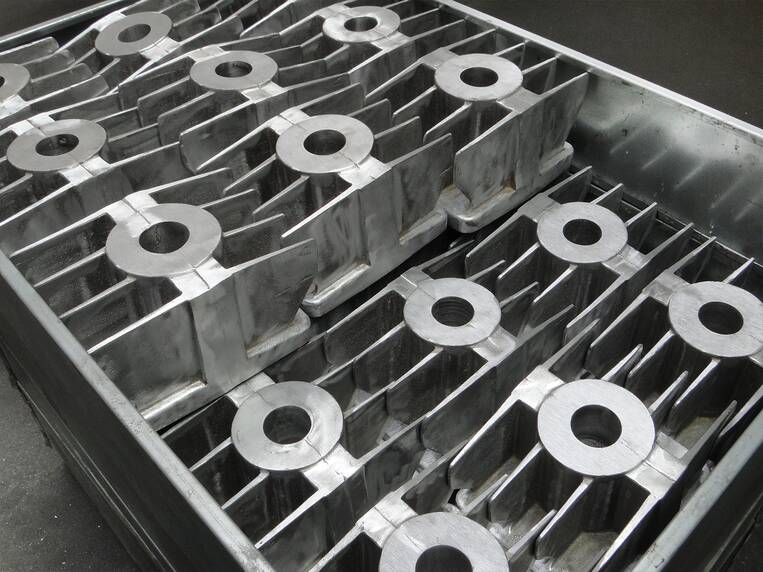

CNC machining (Computerised Numerical Control) is a process in which computer-controlled machines perform precision operations - such as turning, milling or drilling - on metals, plastics or special alloys.

Unlike traditional methods, the entire process is digitally programmed, achieving repeatability and micrometre-level accuracy.

Thanks to the use of CAD/CAM systems, data from the 3D design goes directly to the machine, reducing production preparation time.

Why is it worthwhile for small companies to use CNC machining?

No need to invest in expensive machinery

The purchase of a modern machining centre is a cost of several hundred thousand zlotys. For small companies, such an investment is sometimes difficult to justify.

By outsourcing production to an external partner - such as Eurotech CNC - the entrepreneur pays only for the parts made, without incurring depreciation or service costs.

2. reduced turnaround time

Modern CNC machines operate automatically, often 24/7. This means shorter lead times and the ability to react quickly to changing customer needs.

3 Repeatable quality

Every detail produced using CNC is identical to the previous one. This is particularly important for components that must fit perfectly in the final construction.

4. less risk of errors

The machine carries out the programmed process, eliminating the influence of the human factor. This avoids errors that could generate losses in manual production.

5. production flexibility

Today's CNC centres make it possible to move quickly from one production batch to another. For small companies, this is a huge advantage - they can realise short runs as well as one-off prototypes.

CNC milling and turning - solutions tailored to the needs of SMEs

Depending on the nature of the project, small businesses can benefit from different types of services:

- CNC milling - ideal for the production of flat parts, bodies, holes and grooves.

- CNC turning - used in the manufacture of parts with a rotating cross-section, such as bushings, shafts or couplings.

In both cases, EurotechCNC offers technology consultancy so that even customers without an in-house engineering department can get the optimum solution in terms of cost and quality.

Impact of CNC on small business operating costs

Contrary to what you might think, outsourcing precision metalworking often works out cheaper than doing it in-house.

The savings are due to several aspects:

- no need for a qualified operator,

- reduction in maintenance costs for machinery and tools,

- lower risk of production rejects,

- better use of raw material through process optimisation.

For larger volumes, the cost savings compared to traditional processing can be as high as 30-40%.

CNC machining versus prototyping and short runs

For many small businesses, the ability to rapidly prototype new products is particularly important.

With CNC machining you can:

- produce a single detail within 24-48 hours,

- easy to make design changes,

- go from prototype to small series without additional investment.

This is ideal for companies in the automotive, electronics, tooling or yachting industries, which often test new solutions before implementing them on the market.

Modern technology to increase profitability

The development of digital control systems, sensors and automation means that today CNC is not only fast, but also intelligent technology.

1. automation of processes

The machines work together with material feeding robots to reduce labour costs and downtime.

2. real-time data analysis

With IoT and monitoring software, production parameters are tracked in real time. Deviations can be reacted to immediately and losses can be minimised.

3. CAD/CAM integration

The designer, technologist and operator work on the same data, which eliminates errors and reduces preparation time.

These innovations make CNC machining is also becoming increasingly viable for smaller companies.

Why cooperate with Eurotech CNC?

Eurotech CNC is not only a contractor, but also a technology partner that helps companies optimise their production processes.

Benefits of collaboration:

- experience in implementing projects for SMEs,

- advice on the choice of materials and technology,

- quick quote and flexible deadlines,

- guarantee of reproducible quality thanks to modern machinery.

Thanks to this approach, even a small company can benefit from technology that until recently was only available to the largest players in the market.

CNC machining is not a luxury today, but a real opportunity for small and medium-sized enterprises to increase efficiency and competitiveness.

Thanks to the precision, automation and flexibility of production, this technology allows for shorter lead times, lower costs and improved product quality.

If you run a company that wants to grow without a large investment in equipment, contact Eurotech CNC.

A team of experts will prepare a personalised quote, propose solutions tailored to your needs and help you bring your ideas to life.

Frequently Asked Questions (FAQ)

Yes - CNC allows short batches and prototypes to be realised quickly, without high production preparation costs.

No - Eurotech CNC can help you prepare technical documentation or adapt an existing file.

Automotive, aerospace, electronics, engineering and medical industries - but increasingly also small manufacturing and service companies.

Not if you work with a proven partner. Eurotech CNC uses full dimensional control and certified quality procedures.