Today's industry faces a challenge - how to produce faster, cheaper and with the highest quality? The answer to this question is CNC machining, or computer-controlled processing of metals and plastics. It makes production processes more efficient and unit costs noticeably lower. Companies such as Eurotech CNC use advanced technology and experience to provide customers with parts in less time and at competitive rates, without compromising on quality.

What is the advantage of CNC technology?

Traditional processing methods require manual intervention by the operator, which increases the risk of errors and prolongs the process. In the case of CNC machining The whole thing is computer-controlled - from design to finished part.

Modern CNC machines read data from the CAD/CAM file, converting it into precise tool movements. This means:

- less risk of human error,

- the reproducibility of each element,

- reduced production preparation time.

Automated processes allow machines to run continuously even around the clock - without interruptions or downtime.

Shorter lead times through technology integration

One of the key reasons for CNC machining is so efficient, is the integration of the various stages of production into a single technological environment.

In companies using CAD/CAM systems, the designer, technologist and operator work with the same data. As a result:

- there is no need to enter information repeatedly,

- communication errors are reduced to a minimum,

- Design changes can be made immediately.

Example: in the production of prototypes for a new engine component, the use of CNC machining can reduce implementation time from a few days to a few hours.

Automation and digitisation - the foundation for faster production

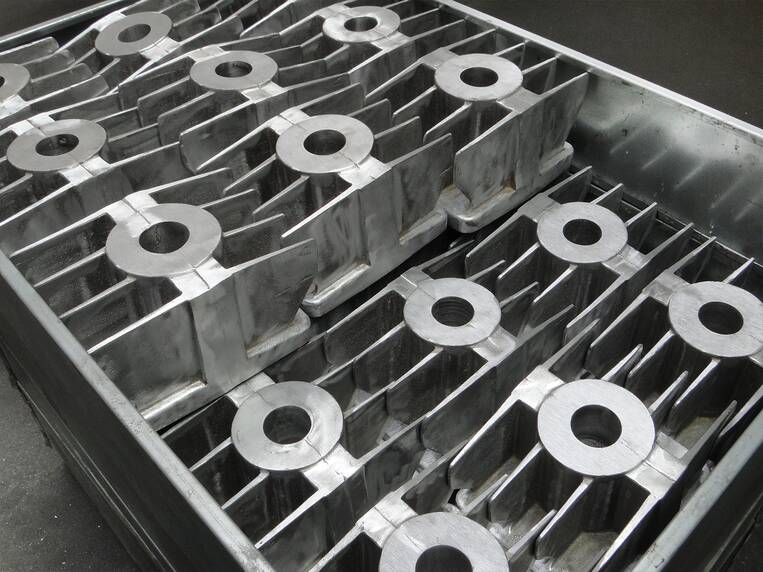

Modern CNC centres are integrated with automatic material feeding systems, tool magazines and measuring sensors. Every step - from clamping the raw material to dimensional control - is performed in an automated manner.

This means that:

- the operator does not have to constantly supervise the machine,

- It takes a few minutes to change production batches,

- measurement errors are immediately corrected by the system.

As a result, CNC milling or CNC turning at Eurotech can reduce production times by up to 40% compared to classic manual machining.

Process optimisation = lower costs

The efficiency of CNC machines is not only about speed, but also about real financial savings.

1. Less material waste

Thanks to precise programming, the tool path can be planned perfectly, minimising material loss.

2. less tool wear

The cutting parameters are selected by computer - always within the optimum range. This means less wear on cutters and turning knives.

3. reduction in labour costs

The operator does not have to perform many repetitive tasks - his role is limited to supervision and quality control.

4 Reduced changeover times

It takes less time to change production from one retailer to another, allowing us to respond more quickly to market needs.

5. elimination of errors and corrections

Each piece is identical to the previous one. There is no need for corrections or rework, which significantly reduces the unit cost.

CNC machining and economies of scale

In traditional production, a large number of parts requires more time and labour. With CNC - the larger the batch, the more cost-effective the production becomes.

The costs of preparing the programme and setting up the machine are spread over a larger number of pieces, which can reduce the unit price by up to several tens of per cent.

This is particularly important for companies in the automotive, electronics or aerospace sectors, where both precision and speed of delivery are important.

When is CNC machining most worthwhile?

Not every production requires full automation, but there are situations where CNC machining brings particular benefits:

- for large production runs,

- in projects requiring a high degree of accuracy,

- in prototyping, where fast response times count,

- in the production of parts made of difficult-to-machine materials such as titanium or stainless steel.

Thanks to the flexibility of CNC technology, the process can be easily adapted to a specific project, without the need for costly production line conversions.

CNC machining is a technology that not only guarantees precision but, above all, shortens production times and significantly reduces costs. Thanks to automation, system integration and process optimisation, it is possible to produce more, faster and cheaper - without sacrificing quality.

If your company is looking for a way to increase production efficiency, contact Eurotech CNC.

Send in your project documentation - and our team of experts will prepare a free analysis and quote, pointing out specific cost reduction opportunities.

Eurotech CNC - your partner in efficient production

Eurotech CNC has been supporting companies in optimising their production processes for years.

The team of technologists, programmers and operators use the latest control systems and CAD/CAM software to ensure the highest quality with minimal lead times.

Why do customers choose Eurotech CNC?

- advanced machinery,

- experience of working with demanding materials,

- individual pricing and cost analysis,

- timeliness and transparent communication.

Working with Eurotech CNC is a guarantee that every project will be carried out precisely, quickly and economically.

Frequently Asked Questions (FAQ)

Not always - for very simple details the differences can be small, but in batch or complex production CNC is definitely more cost-effective.

Project complexity, material, number of operations and production batch size.

Yes - the company carries out both prototypes and large series, tailoring the process to the customer's needs.

Usually within 24 hours of sending the technical documentation.