For many entrepreneurs, cost is a key criterion for choosing a production partner. Customers commissioning CNC machining want to know how much they will pay for a detail, what the unit price is and why similar items may have different pricing. Being transparent is not only a confidence-building exercise, but also a way of raising awareness that cost is made up of many factors - not just machine time.

What is the step-by-step valuation process like?

A quote from a CNC company is not „fortune-telling”, but a precise analysis of the documentation. Most often it looks like this:

- CAD file analysis - checking of geometry, dimensions and tolerances.

- Material selection - cost of purchase and difficulty of processing.

- Machine time estimation - The main cost of production is calculated on this basis.

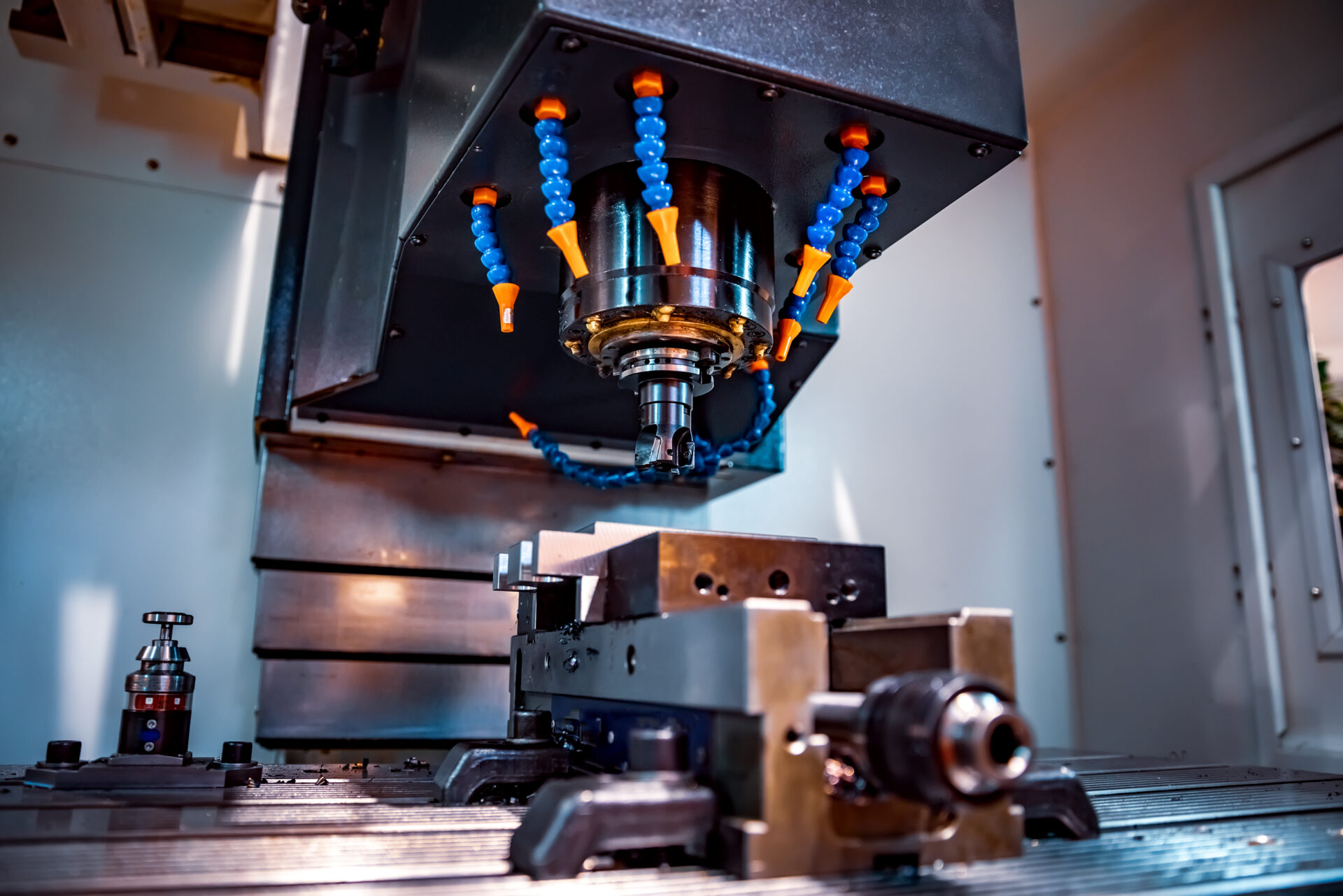

- Determination of the number of operations - whether one process is sufficient or whether additional processes are needed (e.g. drilling, threading, anodising).

- Cost of CAM programming - The more complex the detail, the more time is needed to prepare the code.

- Quality control and packaging - an additional but necessary element of the valuation.

This provides the customer with reliable information on price and lead time.

Key price drivers

1. complexity of the detail

The more pockets, holes, radii and advanced shapes, the longer it lasts machining. Complexity also requires more frequent tool changes, which increases costs.

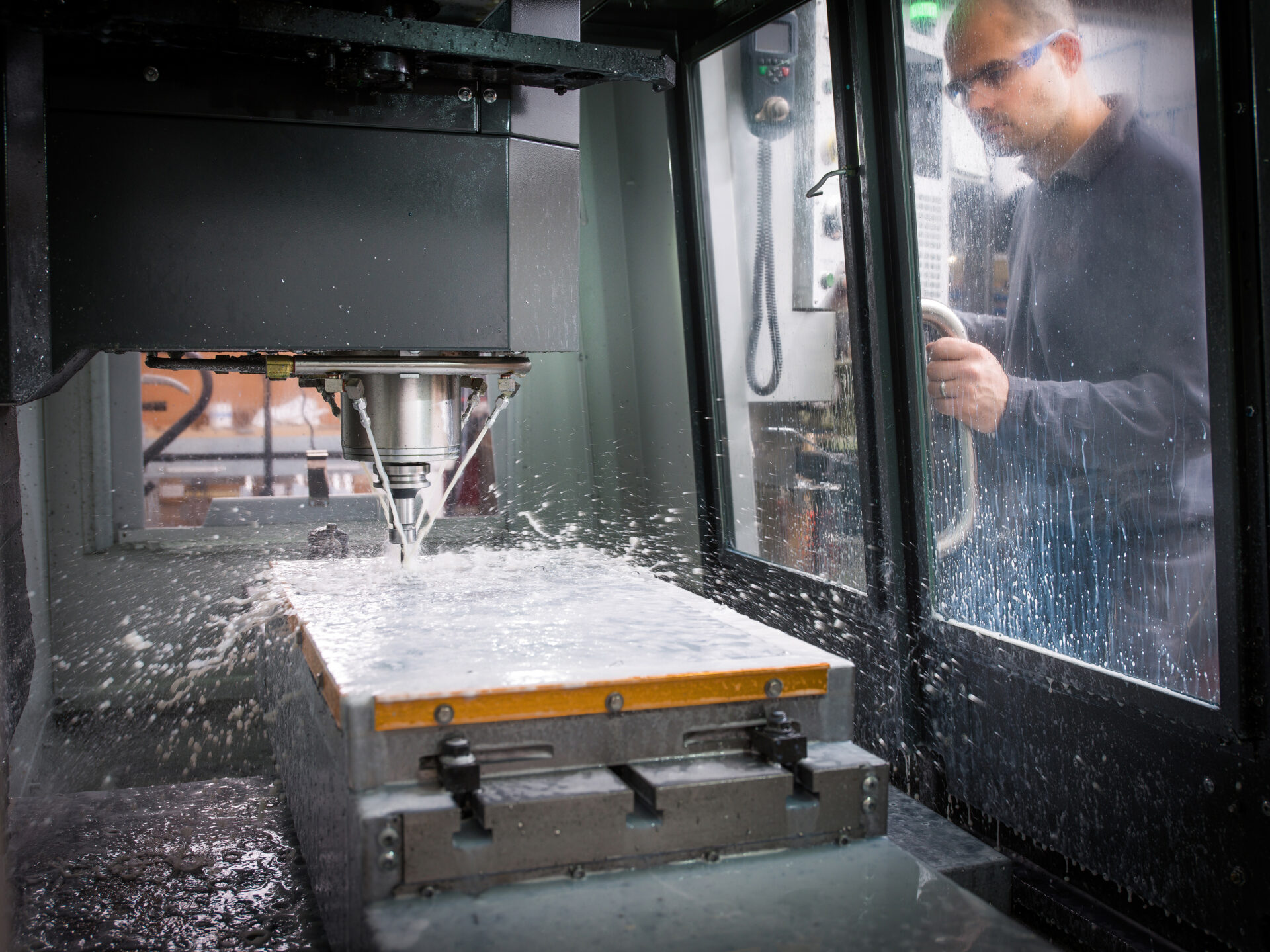

2. operating time of the machine

CNC machines are efficient but expensive to maintain. Every hour of operation has a rate, which includes depreciation, energy and operation. Longer cycle = higher price.

3. production series

A single prototype is always more expensive on a per-piece basis, as the costs of programme preparation and machine set-up are spread over one piece. For larger series, the unit price drops even several times.

4 Material

The ease of processing the material is of paramount importance. Aluminium milling is fast and economical, while stainless steel or titanium require longer and more expensive tools.

5. tolerances and quality of finish

The tighter the tolerances, the more time is needed for implementation and quality control. The same is true for surfaces - a standard finish is cheaper than polishing or anodising.

Hidden costs to be aware of

Often clients focus on the basic price for the treatment, forgetting about the additional elements. The total cost can include, among others:

- logistics and transport - especially with large or heavy details,

- material waste - The less efficiently planned the geometry, the greater the loss,

- preparation of special handles - necessary for unusual shapes,

- certificates and quality documentation - required, for example, in aviation or medicine.

Prototype versus series production - price differences

The difference between prototype and series production is huge.

- Prototype - includes the full cost of programme preparation and machine set-up. The unit price is high, but a quick design check is key.

- Series production - Programming and set-up costs are spread over many components, so the unit price drops. This is ideal for standing orders.

Example: two similar projects, different prices

Imagine two details with the same function:

- Project A - simple shape, standard holes, tolerance of ±0.1 mm.

- Project B - thin-walled workpiece with threaded holes and a tolerance of ±0.01 mm.

Although both perform a similar role, the cost of implementing the Project B can be up to twice as high due to additional operations, longer machine times and more demanding quality control.

How to reduce CNC machining costs?

- Simplify the geometry - avoid unnecessarily complicated shapes.

- Tailor the tolerances - do not use the highest accuracy where it is not required.

- Consider alternative material - cheaper to process if it meets the functional requirements.

- Commission larger series - The larger the production, the lower the unit cost.

- Consult a technologist on the project - an experienced specialist will suggest how to optimise the design.

This approach allows clients to realistically save up to several tens of per cent over the original quote.

The cost of CNC machining depends on many factors - from part geometry, material and tolerances to the number of pieces and lead time. By taking an informed approach to design and working with an experienced partner, you can avoid price surprises and optimise your budget.

Want to know a reliable quote for your project? Contact Eurotech CNC - our experts will analyse the documentation, advise on the best solutions and prepare a quote tailored to your needs.

The role of Eurotech CNC in transparent pricing

Eurotech CNC is committed to transparency. The customer receives not only the final price, but also a detailed analysis of what influences it. This allows him to consciously decide whether, for example, it is worth changing the material, loosening tolerances or simplifying the project. This approach builds partnerships and gives confidence that the pricing is fair.

Frequently Asked Questions (FAQ)

No - with complex designs, CNC proves to be more cost-effective as it eliminates errors and reduces production time.

It all depends on the project - simple aluminium details may cost a few tens of zlotys, but with complex pieces the price goes up.

Yes - production preparation costs are spread over a larger number of units, which reduces the cost per unit.

Unusual materials, complex fixings or additional requirements for finishing and quality documentation.