Machining is one of the oldest and at the same time most developed methods of shaping materials, which, despite its centuries-long history, is constantly evolving. It involves the removal of excess material from the workpiece using suitable tools to give it the desired shape, dimensions and surface quality. Modern technical possibilities make this process not only accurate, but also fast, repeatable and adapted to the requirements of modern industry.

What is the machining process?

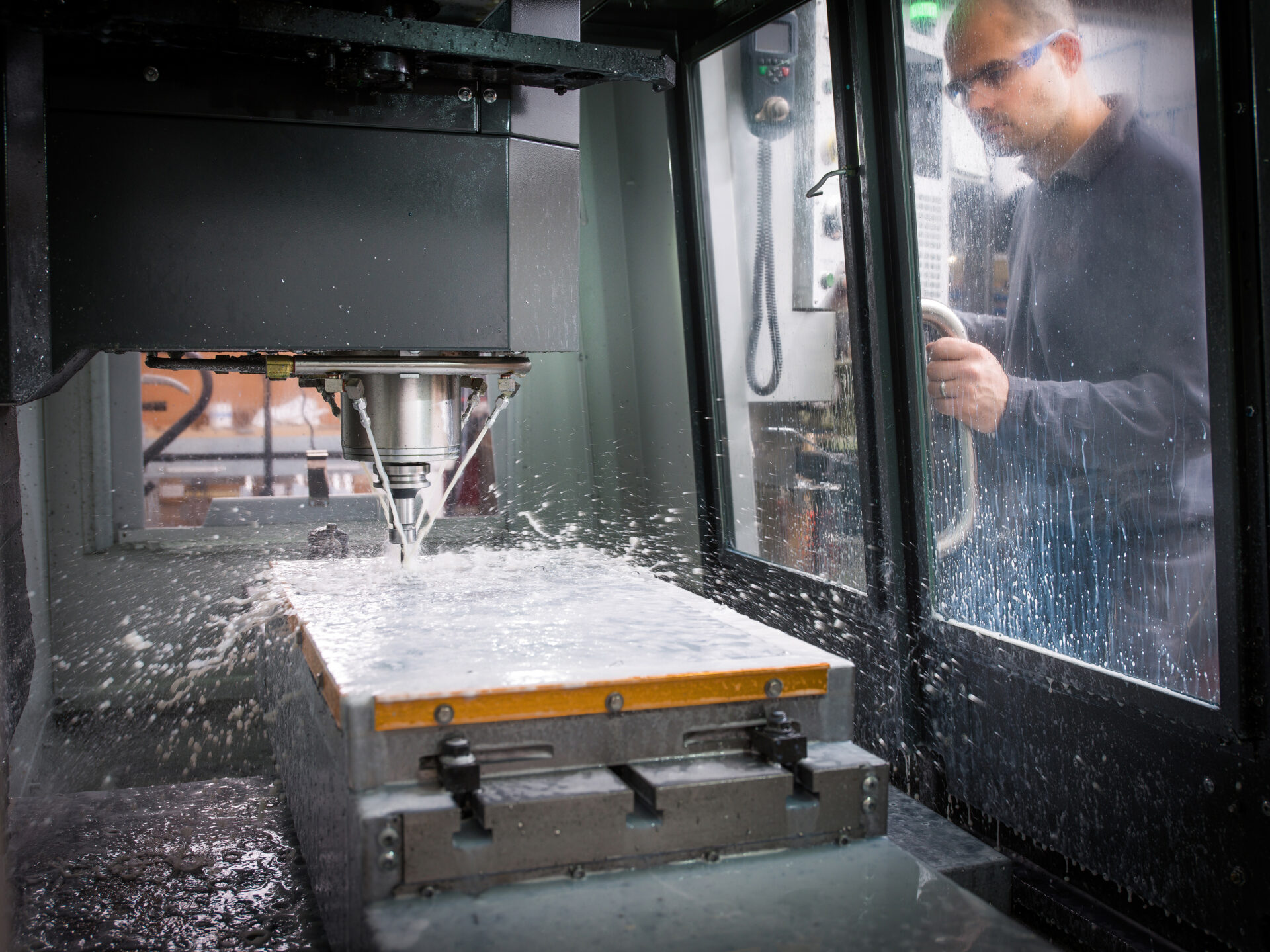

The basis of any process is the right choice of material - this can be structural steel, aluminium, brass, titanium, as well as modern composites or plastics. The workpiece is then clamped in a chuck or vise and the tool, moving in a defined trajectory, removes successive layers of material. The choice of parameters such as speed, feed rate, depth of cut and type of cooling play a key role. Their correct setting translates into precision workmanship, surface quality and tool life.

Tradition and modernity - CNC machining

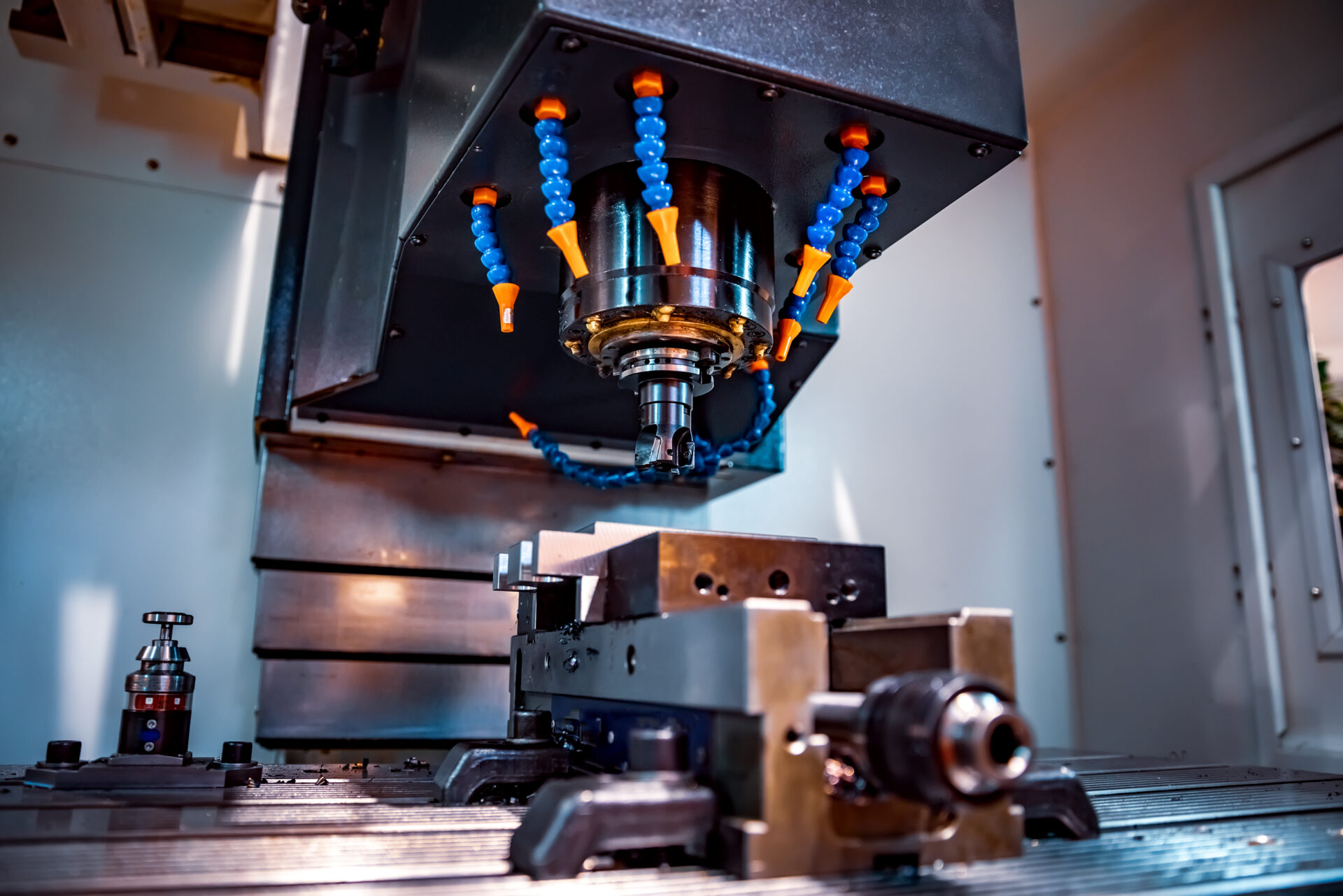

Numerically controlled machines are increasingly used in industry. CNC machining combines traditional cutting principles with precise computer control to eliminate human error and achieve dimensional repeatability even when producing thousands of parts. Thanks to integration with CAD/CAM software, it is possible to transfer the design from the computer directly to the machine and make design changes in no time.

Types of machining

The most commonly used methods are:

- Turning - in which the workpiece rotates about its axis and the tool moves longitudinally or transversely.

- Milling - to produce flat surfaces, grooves, holes and complex spatial shapes.

- Drilling - designed for drilling holes of various diameters and depths.

- Grinding - used to achieve an exceptionally smooth surface.

A special role is played by metal machining indispensable in industries requiring reliability, such as aviation and automotive.

Advantages of modern machining

- Precision - realisation of components with a tolerance of up to a few micrometres.

- Repeatability - guarantee of identical details throughout the series.

- Speed - reduction in production time through automation.

- Flexibility - easy adaptation of parameters to new projects.

- Versatility - the possibility of processing different materials and shapes.

Industrial applications

Machining is used in many industries:

- Automotive - manufacturing of engine components, gearboxes, suspension systems.

- Aviation - manufacture of structural and engine parts.

- Energy - components for turbines, generators and industrial installations.

- Maritime industry - propulsion components and ship structures.

- Medicine - implants, prostheses and surgical instruments.

The future of cutting technology

The future of this method is linked to the further automation and digitalisation of processes. Real-time monitoring of machine operation, data analysis using artificial intelligence and optimisation of energy consumption will become standard. There is also an increasing emphasis on the ecological aspects of production, minimising waste and using longer-life tools.

Thanks to a combination of experienced operators, advanced machinery and high-quality tools, machining remains one of the most versatile, precise and future-proof methods of manufacturing components.

Frequently Asked Questions (FAQ)

Machining is a process in which excess material is removed from a semi-finished part using cutting tools such as cutters, lathe knives or drills. This produces parts with a specific shape and dimensions.

The most common technologies include milling, turning, drilling and grinding. In modern industry, these processes are often carried out on CNC machines.

Steel, aluminium, brass, copper, plastics, as well as difficult-to-machine metals such as titanium can be machined. The choice depends on the specific design and purpose of the component.

In traditional machining, the operator manually controls the machine, whereas in CNC the process is computer-controlled. This ensures greater accuracy, repeatability and shorter lead times.

Yes. Machining works well for single-piece and prototype production as well as for large series. Thanks to the flexibility of the technology, the process can be quickly adapted to the customer's needs.