In modern industry, precision and quality manufacturing play a key role. One technology that has permanently changed the way components are manufactured is the CNC milling. Thanks to computer control, it is possible to achieve parts with complex shapes, as well as full repeatability in series production. However, technology is only part of the success - the selection of the right material is equally important, as it largely determines the strength, aesthetics and cost of the project.

Why is the choice of material so important?

The material from which a workpiece is made affects not only its durability, but also the entire production process. Differences in hardness, heat resistance or density translate into tool selection, cutting parameters and machining time. In practice, this means that the wrong material can significantly increase project costs or production times.

A well-chosen raw material allows:

- increase the life of the component,

- optimise processing times,

- reduce tool wear,

- achieve the desired mechanical and visual properties.

Therefore, the choice of material is as important as the design of the detail itself.

The most common materials used in CNC milling

Aluminum

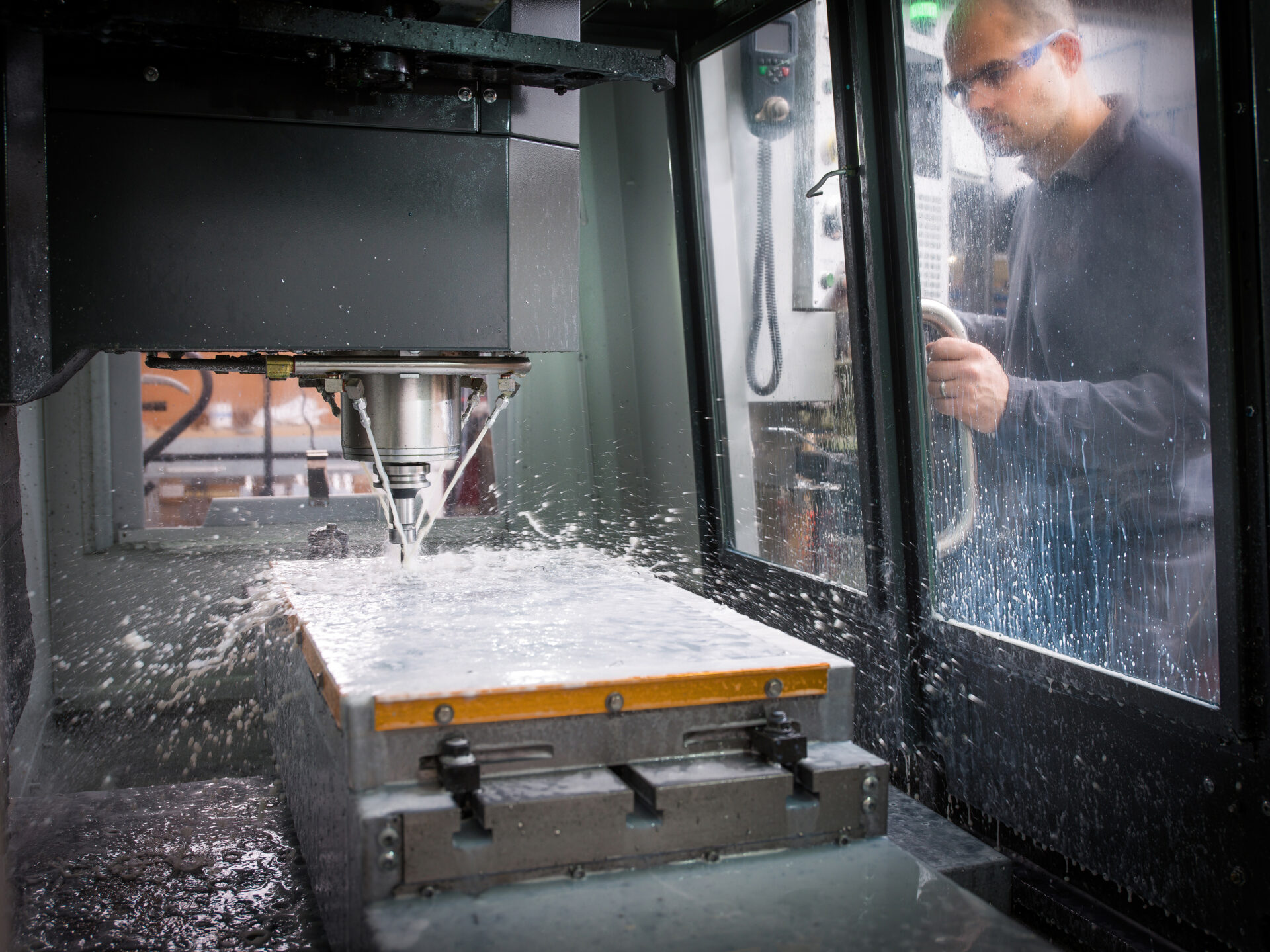

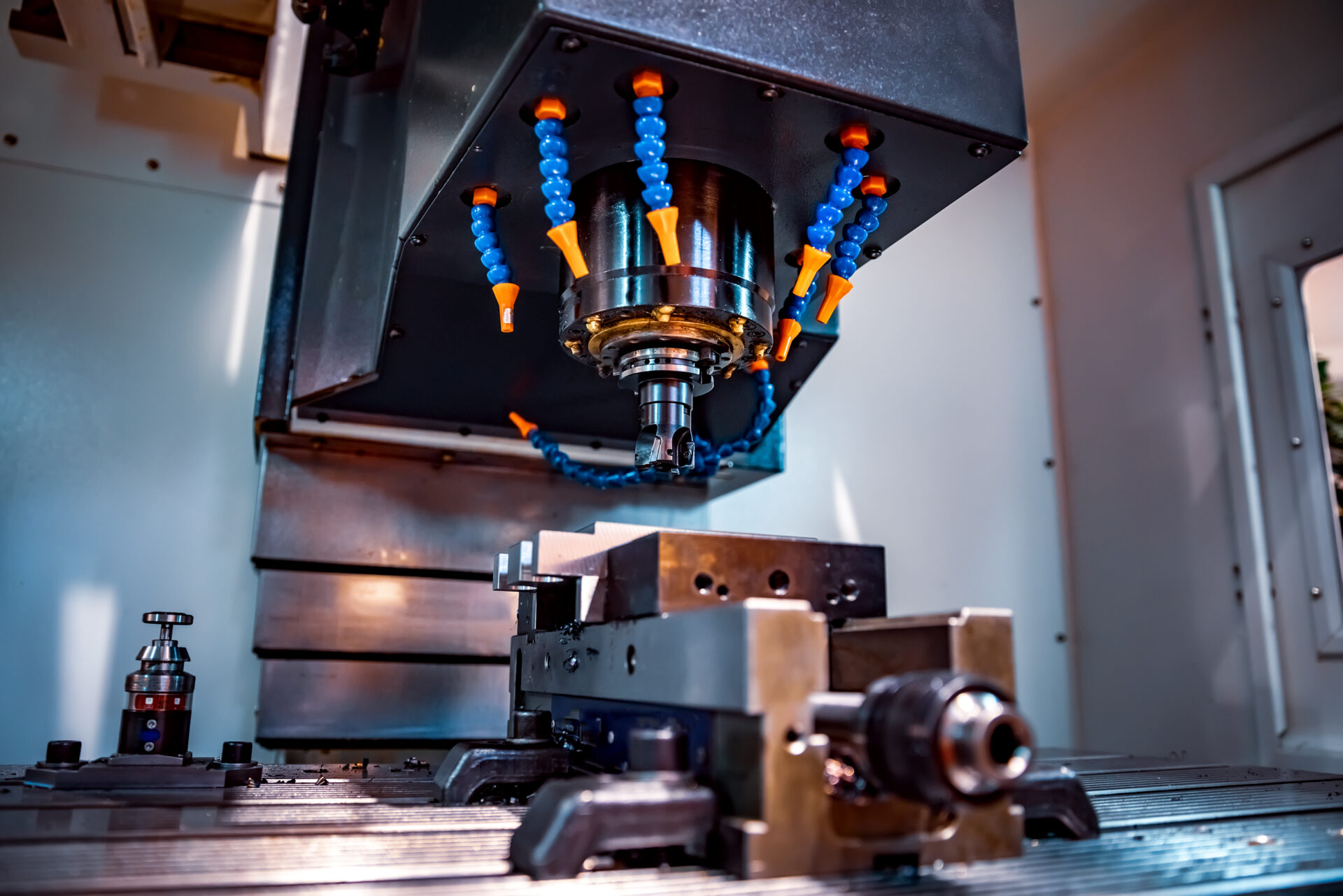

One of the most commonly used raw materials in modern manufacturing is aluminium. Its ease of machining, corrosion resistance and light weight make it an extremely versatile material. Aluminium milling produces components with high accuracy and smooth surfaces, which is of great importance in the automotive, aerospace and electronics industries. It is worth noting that the use of appropriate cooling parameters prevents overheating of the material and guarantees repeatable results.

Steel

The second key material is steel, used where durability and toughness are important. Steel milling requires high-hardness tools and abrasion-resistant coatings, but in return it produces components that are almost indestructible. Steel components are used in machine building, tooling, industrial construction and the energy sector.

Plastics

Polymers are also increasingly being used in industry. The milling of plastics is particularly popular in the medical and advertising industries and in the production of electronic components. Plastics are lightweight, easy to machine and inexpensive, so they are ideal for prototyping or manufacturing components with complex geometries.

CNC milling materials - how to choose?

The choice of material depends on the nature of the project and the usage requirements. It is worth considering criteria such as:

- hardness and mechanical resistance - important for components subjected to intensive loads,

- thermal conductivity - important for parts operating at high temperatures,

- material cost - often decisive in series production,

- aesthetic properties - e.g. colour, gloss or anodising options,

- sectoral destination - Different requirements exist for aerospace components and others for electronics.

Thanks to the market's wide range, it is possible to match the raw material to any application - from prototypes to high-volume production.

Modern trends in material selection

Hybrid and composite materials, which combine the advantages of different materials, have become increasingly important in recent years. An increasing number of companies are also relying on eco-friendly solutions - recyclable raw materials and those whose production involves less energy consumption.

Thanks to developments in technology, materials that used to be difficult to produce, such as titanium alloys and fibre composites, are now being machined. This enables innovative projects in high-tech industries, including renewable energy and transport.

Practical application examples

- Aviation - lightweight aluminium components used in aircraft structures,

- Automotive - steel parts for engines and drive trains,

- Medicine - plastic components, which must be chemically resistant and easy to sterilise,

- Electronics - precision aluminium and plastic housings to protect the ICs.

Each of these industries has different requirements, which is why an individual approach to material selection is so important.

Summary

Choosing the right materials for CNC milling is crucial to the quality and durability of the finished parts. Aluminium, steel or plastic - each of these materials has its own advantages and limitations. The choice of raw material should always take into account the specifics of the project, the budget and the requirements for durability or aesthetics.

Combining the right material with advanced CNC machining technology guarantees components that meet the highest industry standards and perform excellently.

Frequently Asked Questions (FAQ)

The most important criteria are mechanical strength, thermal conductivity, chemical resistance, cost and industry specifics. For example, in aerospace, lightweight aluminium and titanium alloys are preferred, and in mechanical engineering, robust steels

Composite and hybrid materials, which combine the advantages of different raw materials, are becoming increasingly important. Ecology is also an important trend - choosing recyclable materials and environmentally friendly processes.

Aluminium is lightweight, easy to machine and corrosion-resistant. These characteristics make it ideal for the automotive, aerospace and electronics industries, where precision and lightweight components are important.