Designing parts with CNC machining in mind requires a combination of engineering knowledge and workshop practice. Too often, designers focus solely on the functionality of the workpiece, overlooking the limitations of manufacturing processes. The result? Higher costs, extended lead times and sometimes even the inability to make the part. A correct approach to design can significantly reduce financial outlay and speed up production.

The most common design errors

1. Ignoring the limitations of CNC tools

Designers often create parts with very sharp internal corners. Meanwhile, the cutters have their own diameter, which makes it impossible to make a perfectly right angle. This forces additional operations or the use of non-standard tools, which increases costs. The solution is to introduce minimum radii in line with machine capabilities.

2. too thin walls and long, slender elements

Thin-walled workpieces are susceptible to vibration and deformation during machining. A similar problem arises when designing very long components with small diameters. Such designs require additional clamping and reduce production rates.

3. excessive tolerance requirements

Precise dimensions are only needed in key areas of the part. Unfortunately, many designers use very tight tolerances in all dimensions. This forces the manufacturer to use slower cutting parameters and additional control operations. It is worthwhile to adjust tolerances according to real functional needs.

4. lack of planning of workpiece fixing

During design, the question of how the workpiece will be fixed in the machine is often overlooked. If the workpiece does not have suitable base surfaces, special fixtures or additional operations have to be created. This increases both the time and cost of the whole process.

5. Poorly designed holes and threads

Open through-holes are much easier and cheaper to produce than blind holes with large depths. Similarly, threads - those with standard dimensions and short lengths are quick to produce, while unusual solutions may require special tools.

6. over-complicated geometries without real need

Some designs involve very complex shapes, which in practice do not improve the functionality of the component. The more complex the geometry, the more time the machine spends executing the programme. Simplicity is one of the key elements of effective design for CNC machining.

7. Inappropriate choice of material

The most expensive material is not always the best choice. Aluminium milling is fast and economical, and the material itself is lightweight and corrosion-resistant. If the function of the workpiece does not require stainless steel or titanium, choosing a simpler material will significantly reduce production costs.

Consequences of design errors

Design errors have a direct impact on cost and quality:

- More operations - Complex details require additional tool passes.

- Increased processing time - especially with excessively tight tolerances.

- Higher tool costs - the need for special cutters or holders.

- Production discards - deformation of thin walls or fixing problems.

- Delays in processing orders - longer machine set-up and quality control times.

In practice, each of these factors translates into lower company competitiveness and financial losses.

How to avoid mistakes in designing for CNC?

- Cooperation with the technologist - analysis of the project before production starts.

- CAM simulations - verification of tool paths and potential collisions.

- Rational tolerances - matching the accuracy to the function of the workpiece.

- Geometry optimisation - avoiding unnecessary complex shapes.

- Material selection - selecting raw materials that provide durability at minimum processing cost.

- Prototyping - making trial components prior to the start of series production.

Designing for CNC machining requires knowledge of technological and economic constraints. Errors such as too thin walls, excessive tolerances or inappropriate material selection significantly increase costs and lead times.

If you want to be sure that your project will be carried out optimally, contact Eurotech CNC. Our experts will help you right from the design stage to ensure that the final piece meets all quality requirements and is produced in the most cost-effective way.

How does Eurotech CNC support its customers?

Design errors can be eliminated by working with an experienced partner. Eurotech CNC offers:

- advice already at the design stage,

- verification of CAD models for feasibility,

- advanced simulation and CAM programming,

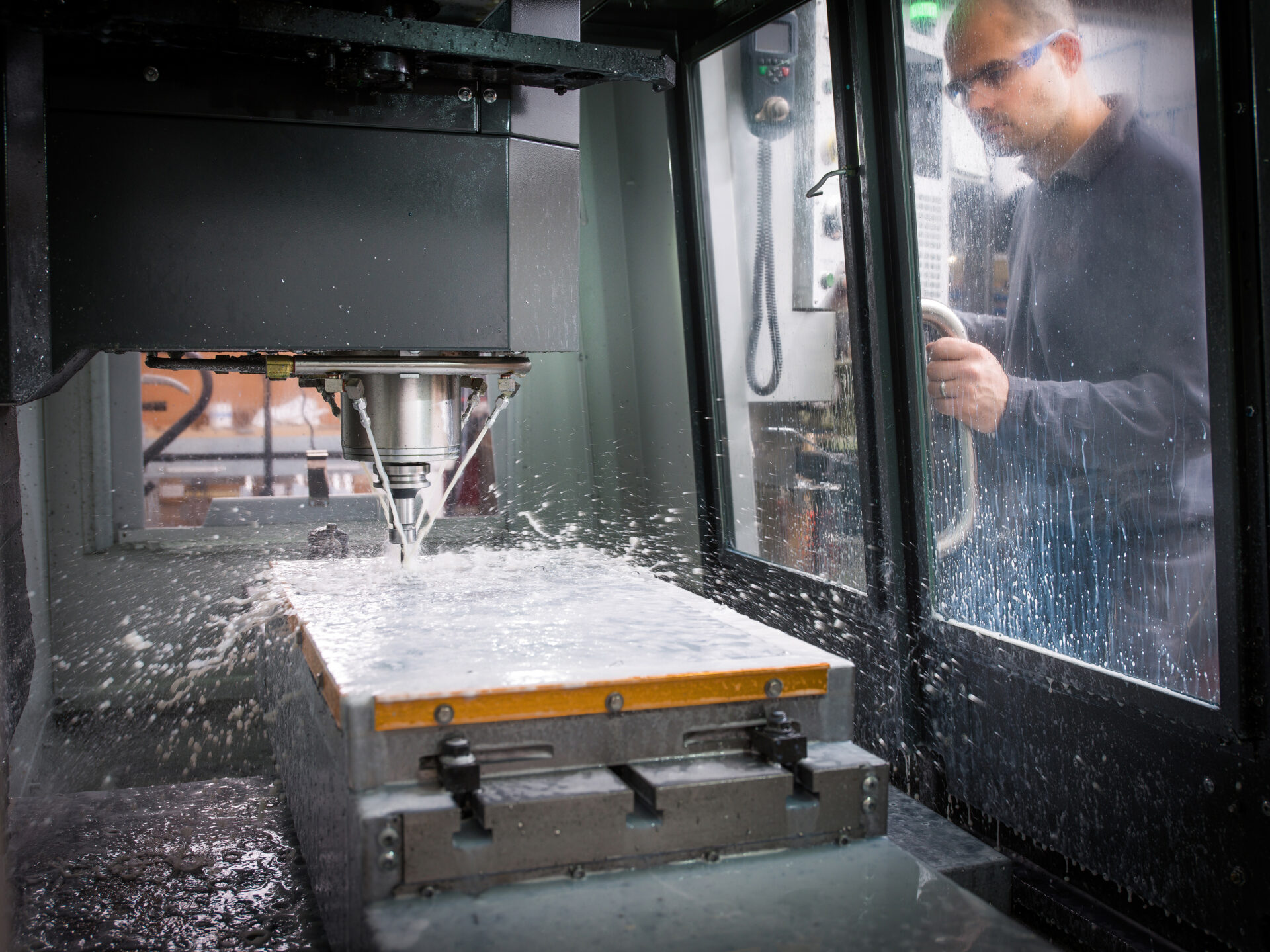

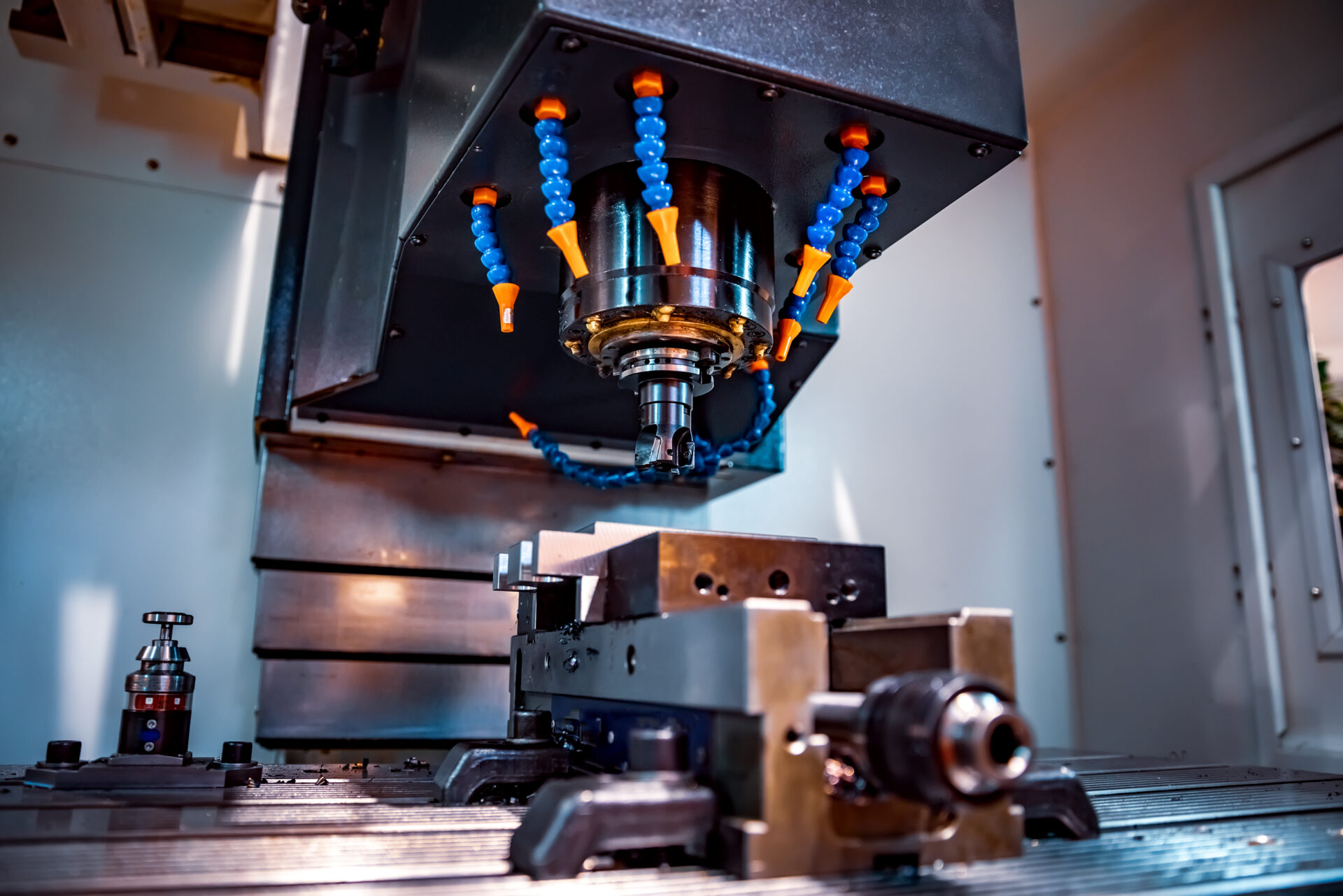

- modern machinery adapted to a wide range of projects,

- years of experience working for the automotive, aerospace and medical industries.

This ensures that customers receive items that are in accordance with the design, made quickly, precisely and without unnecessary costs resulting from design errors.

Frequently Asked Questions (FAQ)

The most common issues are too small corner radii, unnecessarily complex shapes and excessive dimensional tolerances.

Yes - they require additional surgery and can deform. It is worth avoiding them if they are not necessary.

It is best to consult a technologist or simulate it in a CAM programme.

Because it affects both machining time and cost. Aluminium is cheaper and quicker to machine than steel or titanium.