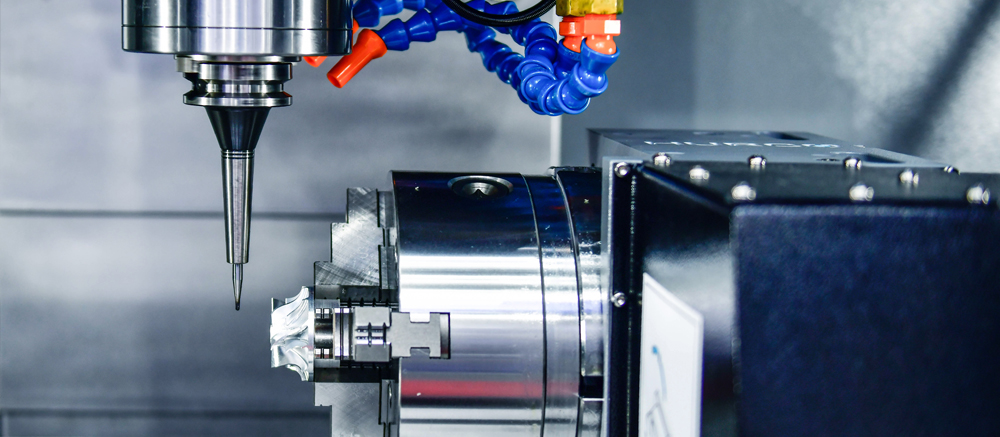

CNC turning - precision and repeatability in every detail

CNC turning is one of the most precise and repeatable methods of processing metals and plastics. In the company Eurotech CNC We specialise in fulfilling orders for customers from a wide range of industries - from the engineering and automotive sectors to the energy sector and the manufacture of customised components.

Our strength is our modern machinery, experienced operators and advanced CAM software, which allows us to carry out even the most demanding projects. Every detail is created with attention to accuracy, repeatability and timely delivery.

What is CNC turning?

CNC (Computerised Numerical Control) turning is a machining process in which a workpiece - usually in the form of a bar or shaft - is set in motion and a cutting tool moves against it in a strictly programmed manner.

Thanks to numerical control, it is possible to achieve smooth surfaces, perfectly reproduced shapes and dimensions with a tolerance of up to ±0.01 mm.

Compared to traditional manual turning, CNC technology provides:

much greater precision and repeatability of dimensions,

the possibility of series production with identical parameters,

reducing production cycle times,

fully automated and secure process.

This makes CNC turning indispensable wherever quality and accuracy count - from small precision bushings to long, large-diameter components.

Our technological capabilities

At Eurotech CNC, we have state-of-the-art production facilities that allow us to carry out complex projects and components with high quality requirements.

Our lathes enable a wide range of workpieces to be machined - from small components to large structural parts.

FAMOT 400 lathe

Ideal for precision machining of larger workpieces with large diameters and lengths. Provides high operating stability, structural rigidity and excellent repeatability even with long turning cycles.

RAIS 250 Lathe

Works well for turning CNC smaller parts where accuracy and surface quality are crucial. Enables complex parts to be produced quickly and efficiently.

Technical parameters:

Diameter range

down 250mm

Turning length

down 500mm

Manufacturing tolerances

± 0.01mm

Advanced CAM software combined with the experience of our operators enables the creation of parts with complex geometries, with the highest precision and surface quality.

In addition, our CNC turning stations are equipped with cooling and tool monitoring systems, allowing full control over the process and reducing material consumption.

Materials we process

At Eurotech CNC, we realise that the selection of the right material is crucial to the quality and durability of the finished component.

We therefore offer CNC turning of metals and engineering plastics, adapting the machining parameters to the properties of each raw material.

Our experience includes:

Structural steel - versatile and durable, ideal for industrial applications.

Stainless and acid-resistant steel - used in the food, chemical and medical industries.

Aluminum - light, rigid and easy to process, ideal for precision parts.

Brass and copper - with excellent thermal and electrical conductivity, used in the electrical industry.

Engineering plastics (POM, PA, PEHD, PTFE) - used where low weight, chemical resistance and durability are important.

Special and difficult-to-machine alloys (Inconel, Hastelloy) - used in demanding industrial, energy and aerospace applications.

In the case of unusual materials or components with unique properties, our technologists develop individual machining strategies, selecting tools, parameters and cooling to achieve an optimal result.

On request, we also realise the turning of our own or entrusted materials.

Comprehensive support for CNC turning processes

Eurotech CNC offers not only the machining itself, but a full service for the production process. We start each project by analysing the technical documentation and then proceed through the stages:

technology advice and model preparation,

development of toolpaths in CAM software,

CNC turning and dimensional inspection,

possible surface finishing, cleaning and assembly,

final quality verification.

This provides the customer with a finished product that fully complies with the technical drawing and the requirements of industry standards.

Our aim is to provide a comprehensive CNC machining service that eliminates the need for multiple subcontractors.

Why is Eurotech CNC a good choice?

Modern CNC lathes - a guarantee of precision and process stability,

Experienced team of operators and technologists,

Individual approach to each project,

Fast lead times and production flexibility,

Quality control at every stage,

Transparent communication and technical support.

At Eurotech CNC, we focus on a combination of technology, experience and reliability. Thanks to this, we are able to meet even the most demanding expectations of our customers, providing products that combine precision workmanship, durability and aesthetics.

Trust the CNC turning specialists

Are you looking for a partner who will complete your projects with the utmost accuracy and within a short timeframe?

Choose Eurotech CNC - a company that has been providing professional CNC turning and metalworking solutions for years.

Contact us to find out how we can help with your project.

CNC Turning - Frequently Asked Questions (FAQ)

Yes – we carry out both single parts and medium-series orders.

Just send a technical drawing or 3D model and specify the quantity. We usually respond within 24 hours.

Yes, upon request we offer support in the field of DFM (Design for Manufacturing), i.e. adapting the project to technological possibilities.

The formats we most frequently use are: PDF, DWG, DXF, STEP, IGES.

Yes, we also process technical materials such as POM, PA, PE-HD. We select turning parameters to suit the properties of a specific material.

Of course – we advise which material will be the best in terms of durability, resistance and cost of production.

Depending on the complexity of the project – even 2–3 working days for simple details. We price each order individually.

Yes, we provide courier shipping or delivery within Poland and the EU.

Yes – we can prepare a test series before moving to full-scale production.