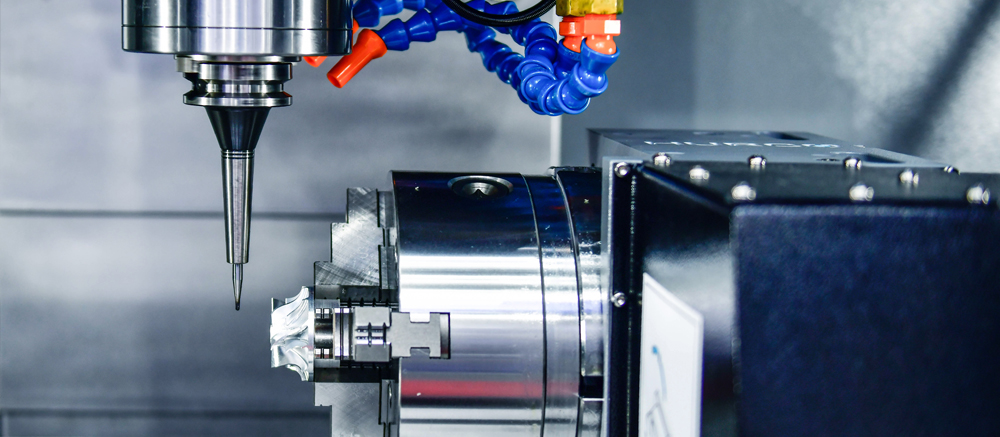

CNC turning

CNC turning is one of the most precise and repeatable methods of metal and plastic processing. At Eurotech CNC, we specialize in the implementation of orders for clients from various industries - from the machine industry, through automotive, to the production of individual elements on individual orders. Our advantage is experience, modern machinery and full commitment to each project.

What is CNC turning?

CNC turning (Computerized Numerical Control) is a machining process in which the workpiece – usually a rod or shaft – is set in rotation, and the cutting tool moves relative to it in a precisely programmed manner. As a result, it is possible to obtain precise shapes, smooth surfaces and exact dimensions – with an accuracy of even tenths of a millimeter.

Compared to traditional manual turning, CNC turning offers not only greater accuracy, but also the possibility of serial production while maintaining uniform quality parameters.

Our technological capabilities

At Eurotech CNC we have modern production facilities that allow us to carry out complex projects. Key machines used for CNC turning are:

FAMOT 400 lathe

ideal for precise machining of larger, large diameter and long workpieces, ensuring stability and high performance.

RAIS 250 Lathe

It is suitable for turning smaller, precise elements that require accuracy and dimensional repeatability.

Technical parameters:

Diameter range

down 250mm

Turning length

down 500mm

Manufacturing tolerances

± 0.01mm

Our CAM software and the experience of our operators enable us to produce details of complex geometry and requiring high precision.

Materials we process

At Eurotech CNC we understand how crucial the quality of the final product is. appropriate selection of material. That is why we offer CNC turning of a wide range of materials – both metals and plastics – adjusting processing parameters to their individual properties. Our experience includes both standard and difficult-to-cut materials that require appropriate tools and technological strategies.

Structural steel – universal, durable and economical, ideal for many industrial applications.

Stainless and acid-resistant steel – used where corrosion resistance is important, e.g. in the food, chemical and medical industries.

Aluminum – light and easy to process, with high mechanical strength and good thermal properties.

Brass and copper – perfect for components requiring good thermal or electrical conductivity and abrasion resistance.

Technical plastics (POM, PA, PEHD, PTFE) – perfect for applications where lightness, chemical resistance and a low coefficient of friction are required.

Special and difficult-to-machine alloys (e.g. Inconel, Hastelloy) – used in advanced industrial and energy applications where exceptional durability and resistance to high temperatures are required.

In case of unusual materials or projects requiring additional analysis, our technologists select appropriate tools, speeds and cooling to guarantee the highest quality and stability of the production process. We are also open to processing materials provided by the customer – after prior technical agreement.

CNC Turning - Frequently Asked Questions (FAQ)

Yes – we carry out both single parts and medium-series orders.

Just send a technical drawing or 3D model and specify the quantity. We usually respond within 24 hours.

Yes, upon request we offer support in the field of DFM (Design for Manufacturing), i.e. adapting the project to technological possibilities.

The formats we most frequently use are: PDF, DWG, DXF, STEP, IGES.

Yes, we also process technical materials such as POM, PA, PE-HD. We select turning parameters to suit the properties of a specific material.

Of course – we advise which material will be the best in terms of durability, resistance and cost of production.

Depending on the complexity of the project – even 2–3 working days for simple details. We price each order individually.

Yes, we provide courier shipping or delivery within Poland and the EU.

Yes – we can prepare a test series before moving to full-scale production.